CAPTURE

Equipment is typically installed at CO2 sources to capture, purify, and liquify the CO2 to prepare it to be transported to wells that will inject the CO2 deep underground

- Carbon capture facilities can usually be added to facilities without interrupting normal operations

- Depending on the CO2 concentration from the industrial process, carbon capture technologies vary. Traditional (amine) capture has been joined by more complex (membrane), and experimental (cryogenic) technologies

TRANSPORTATION

The liquid gas is gathered and transported via a dedicated CO2 piping system to the nearby sequestration site

- CO2 is non-combustible

- 24/7 transportation monitoring and control

SEQUESTRATION

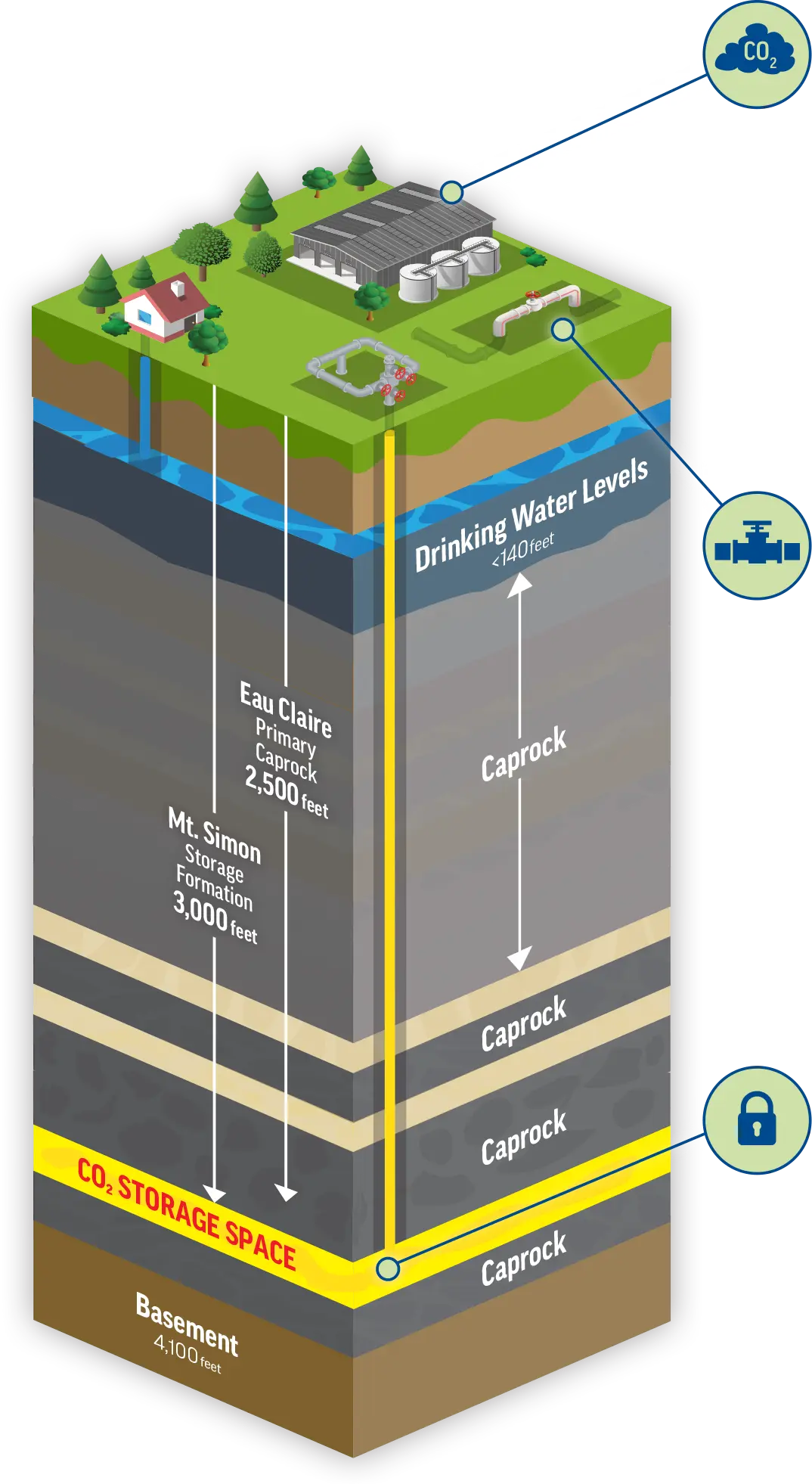

CO2 is injected into the ground beneath an impermeable layer of rock for safe and permanent storage, or sequestration

- Geologic sequestration requires a reservoir with ample permeability and porosity and a dense layer of caprock that prevents the vertical movement of CO2

- The U.S. Environmental Protection Agency (EPA) has intensive permitting, monitoring and reporting programs to ensure CO2 is safely and permanently sequestered

- By definition, CO2 sequestration is non-damaging to natural formations and produces no fossil fuels